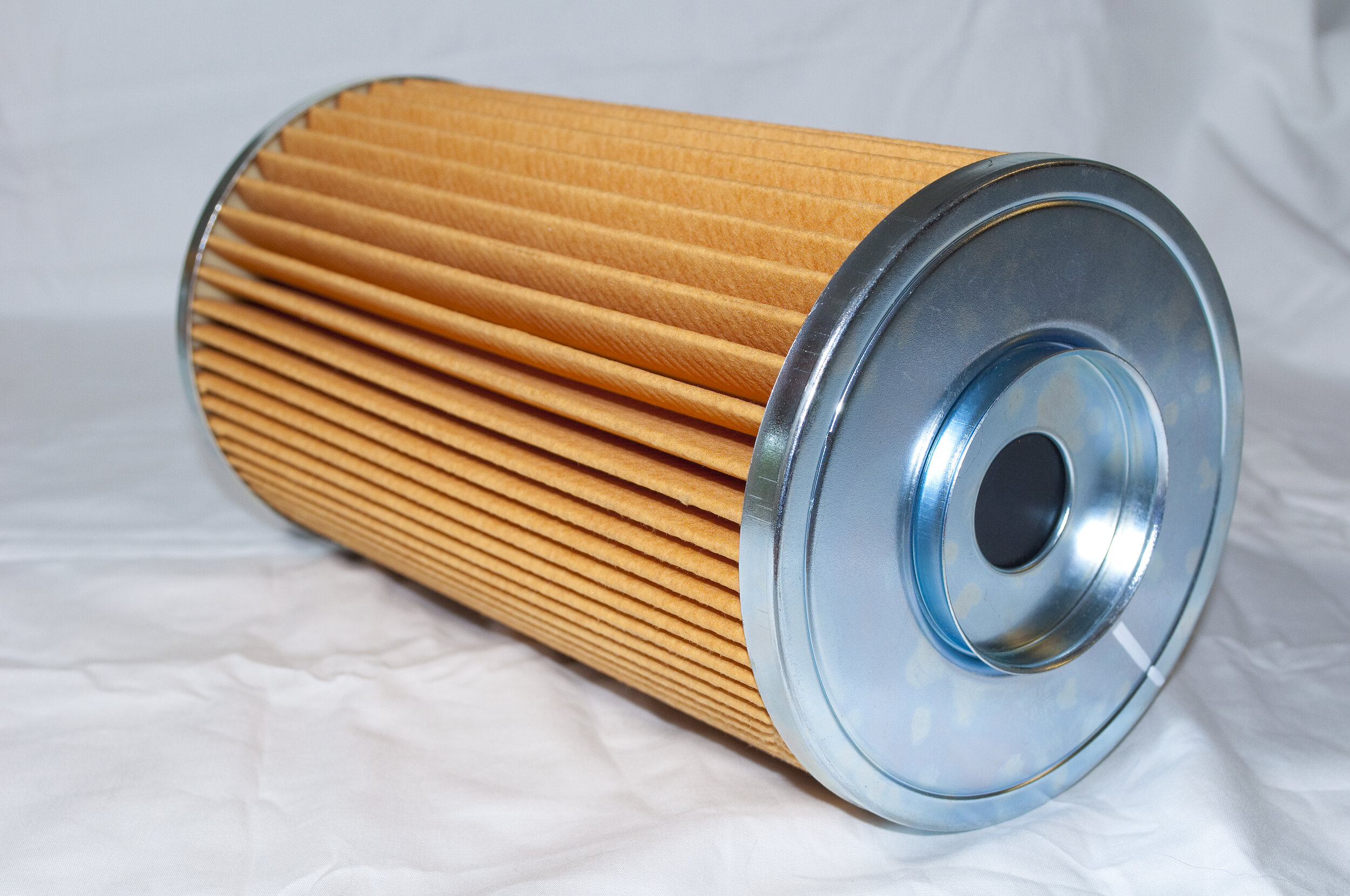

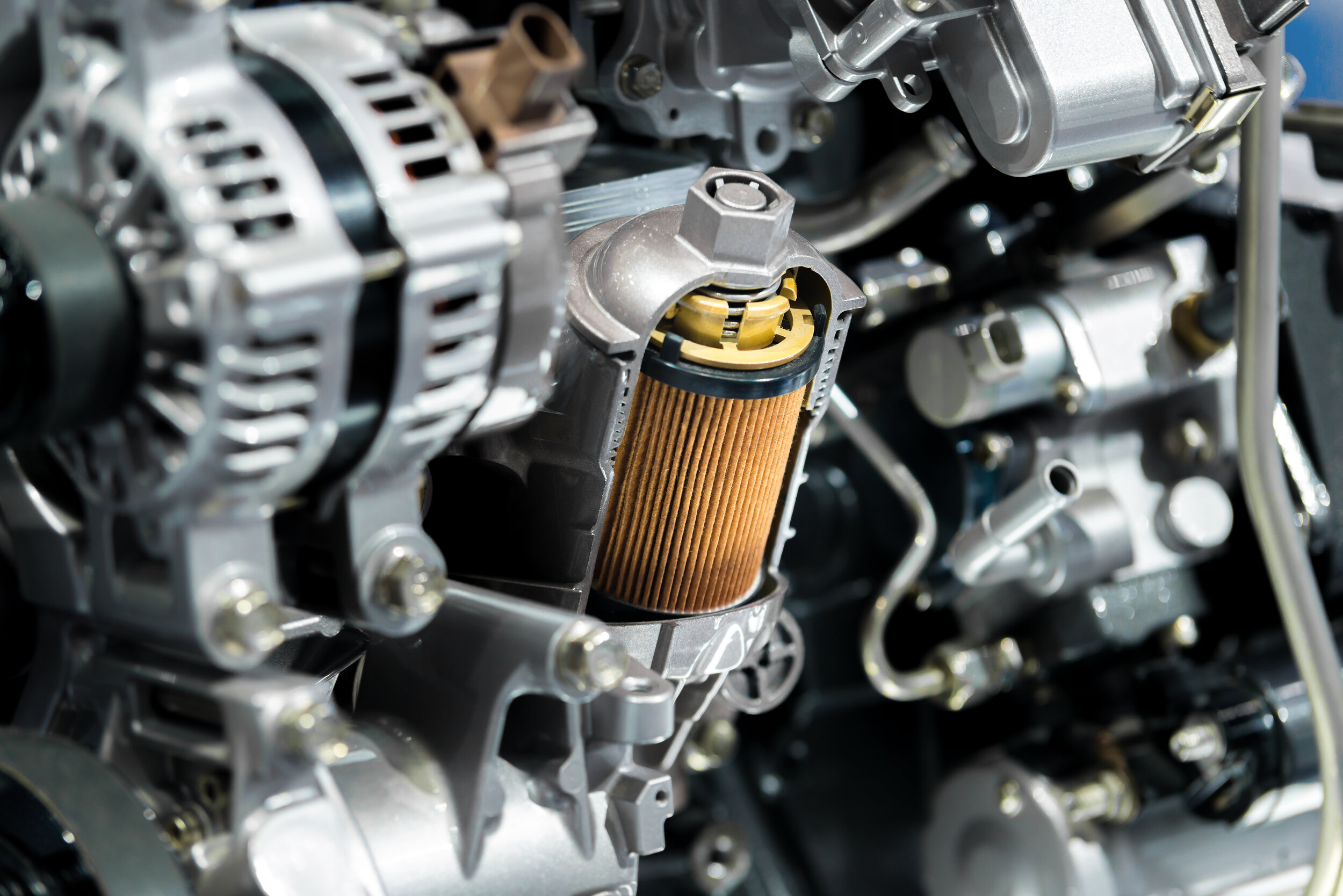

New line of filter sheets called DKF B/A, was specifically developed to meet the requirements of both the chemical and food industries. The manufacturing of DKF B/A filter sheets is made possible due to Omnia’s unique composite technology, which allows the in-line jointing of a double layer. One side is made of a proprietary blend of Kieselguhr and cellulose, while the other side is pure cellulose.

The advantage: A + B = C

(A) Entering Side of the Filter - The Kieselguhr layer creates a higher efficiency to allow superior brightening and sterilizing.

Plus

(B) Exiting Side of the Filter - The cellulose side provides a protective finish, which guarantees a higher mechanical resistance during the filtration process.

Equals

(C) The Total Advantage - Simply a filter with superior filtration retention, at dramatically higher flow rates

1 | |||

|---|---|---|---|

2 | Colors | White, & Tan | |

3 | Composition | Cellulose, Cotton, Diatomaceous earth/ Kieselguhr, synthetic fibers, perlite, resins | |

4 | Surface | Smooth | |

5 | Caliper | 0.125 inches | 3,2 mm |

6 | Basis Weight | 860 lbs. to 950 lbs./3000 ft2 | 1400 g/m2 to 1550 g/m2 |

7 | Characteristics | Superior filtration retention ant dramatically higher flow rates. | |

8 | End Uses | • Filtration of liquids that are slightly viscous, wines, liqueurs, spirits, liquid sugar, glucose, food and mineral oils, ciders and solvents; alcoholic extracts, cognac, whisky, water containing metal oxide, clarifying of extracts, elimination of metal traces; brightening-sterilizing, a beer finisher. • Produced for double filtration of recovered vegetable and food oil. Brightening of all pharmaceutical, food and cosmetic liquids also for essential oils. | |

Other Filtration Media: