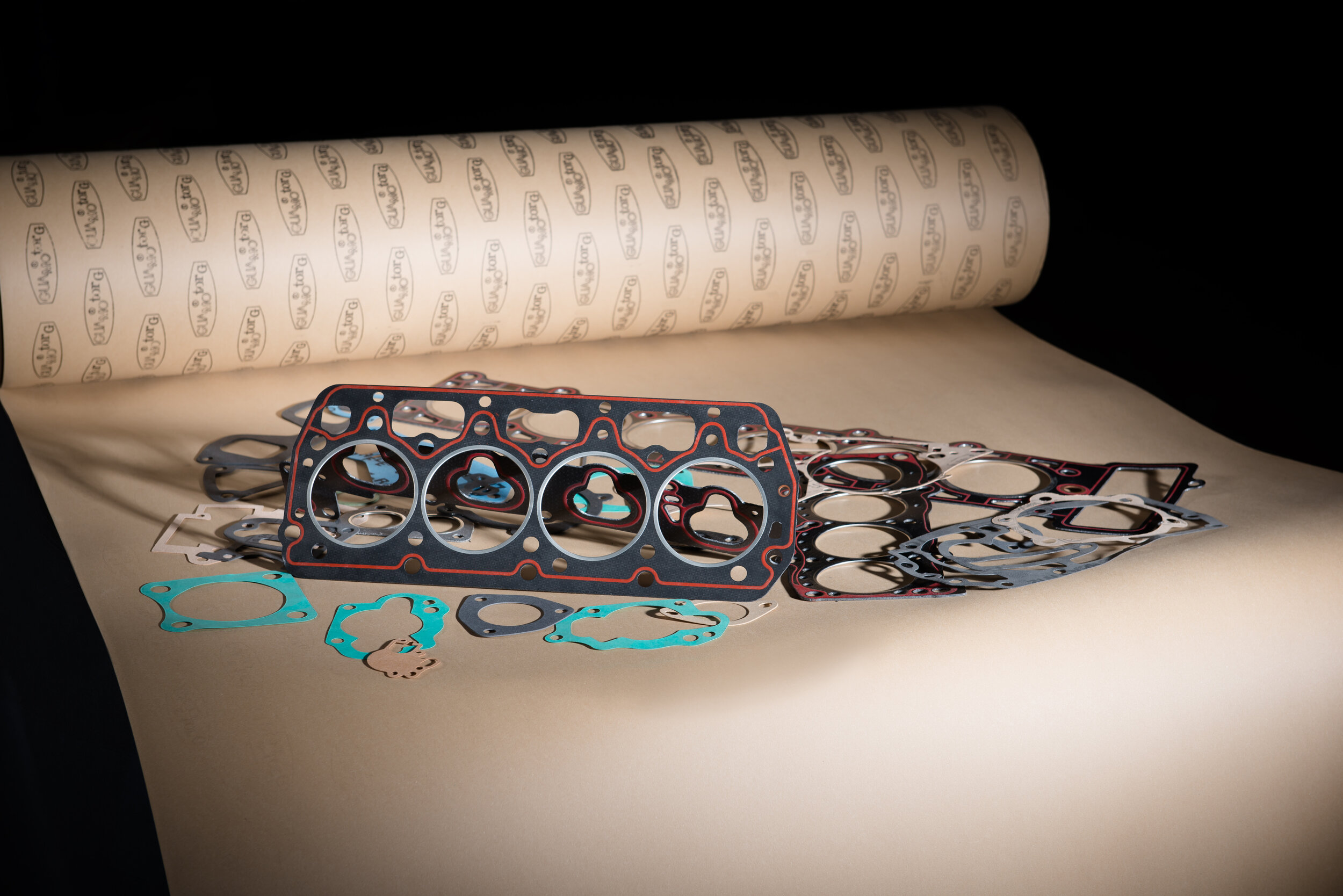

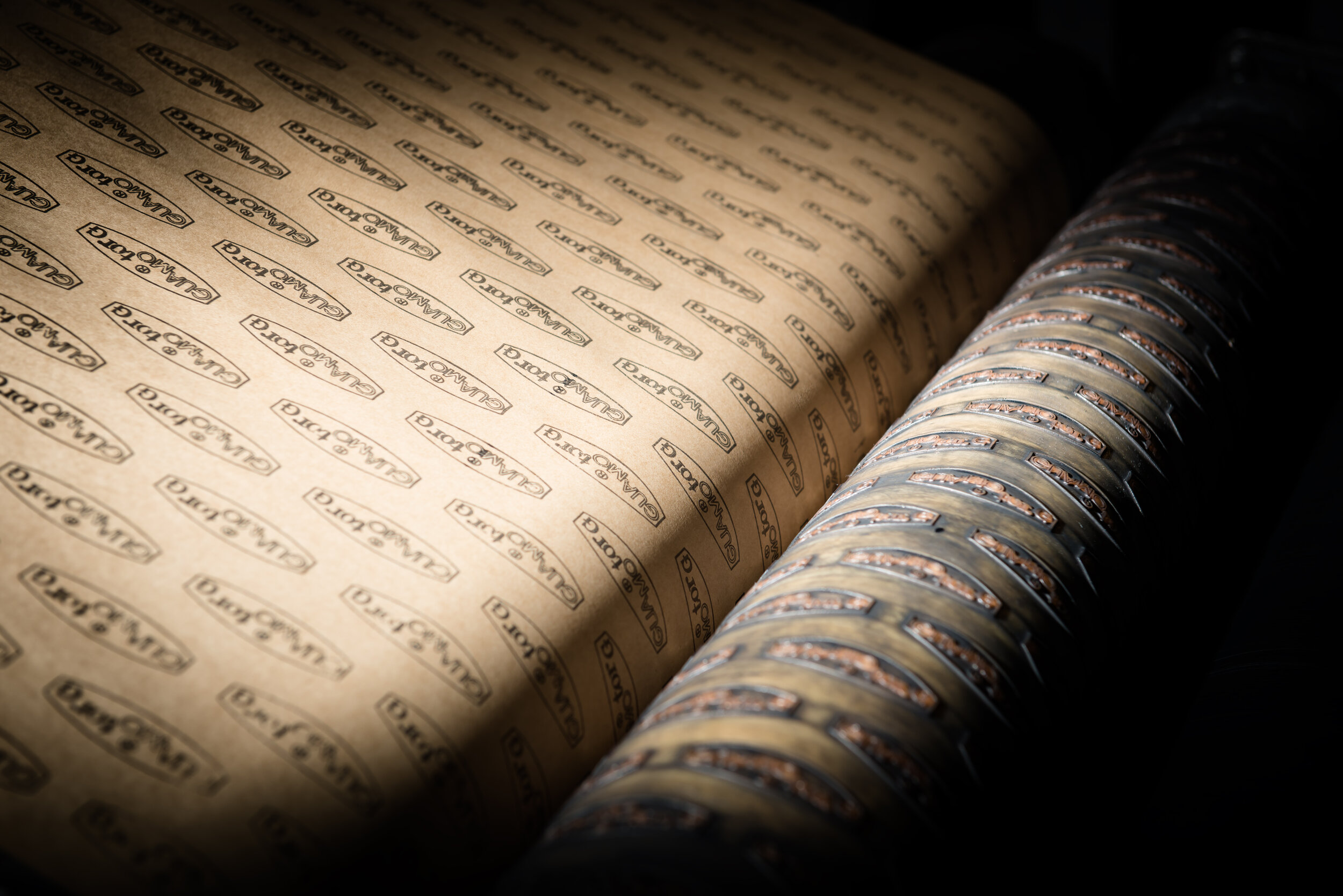

Automotive: more compact engines develop higher compression and thus, higher temperatures environment. Omnia’s fibre materials are developed to sustain higher stress resistance, keeping highest levels of selalibiliy existing in the market. Highest temperatures requirement, like cylinder head, exhaust or heat shielding could find several options among our large material portfolio of metal-fiber materials using appropriate sulfur free fiber sealing or Graphite metal materials. Heat shielding materials protect car carbines from heat developed by more compressed engines.

Heavy Equipment & Machinery: heavier loads and longtime exercise, are heavily stressing equipment engines and, consequently, sealing and heat materials workloads. Omnia experience is able to assist customers for the proper choice of compressed metal-fiber and heat shielding solutions.

Heavy Duty: high demanding performances are required in each part of engine, trasmission and compressors. Whereas aggressive compression or/and heat is developed, demanding sealing properties requires a wide range of fibre materials and excellent heat shielding material properties.

Small Engines (bikes/leisure/sport vehicles): usually requires competitive fibre materials resisting to high torque, in aggressive environments (sand, snow, sea water, mud etc), Graphite metal, metal-fiber and heat shielding solutions to support sealing and protecting high temperature compressed engines.

Industrial: in pumps, valves and thermohydraulic applications, where a good Pressure and Temperature (P/T) ratio is required, highly compressed fibre materials, Graphite metal or solid metal core materials offer a good alternative of solvent base calendared sheets.