With 60+ years of successful product development and innovation, let’s create solutions together.

At Omnia, we attract and enjoy a select, diverse and imaginative set of customers who entrust and challenge us with proprietary and non-proprietary products.

Our Custom Products category is truly a diverse lot and best exemplifies Omnia’s capability of blending talent, experience, technology, agility and flexibility to quickly take products from concept to reality. As a result, Omnia is able to respond quickly to customers with special needs or requests.

End products are crafted from various combinations of natural and man-made fibers including many species of wood pulp, cotton and synthetics, as well as both organic and inorganic fillers, resins and latex reinforced fibers.

If you can imagine it, Omnia can help to create it:

Filtration companies are always looking for alternative solutions to meet their demanding applications and ever-changing media needs. Fortunately, Omnia has been there to meet these challenges with proven success from Automotive Filtration to Food and Beverage solutions.

Omnia manufactures highly absorbent media for World-Class technology leaders who provide patented technology for use in hospitals, retail facilities, office buildings, industrial sites, and many other applications where corrosion protection, condensation control, and mold and mildew control are required.

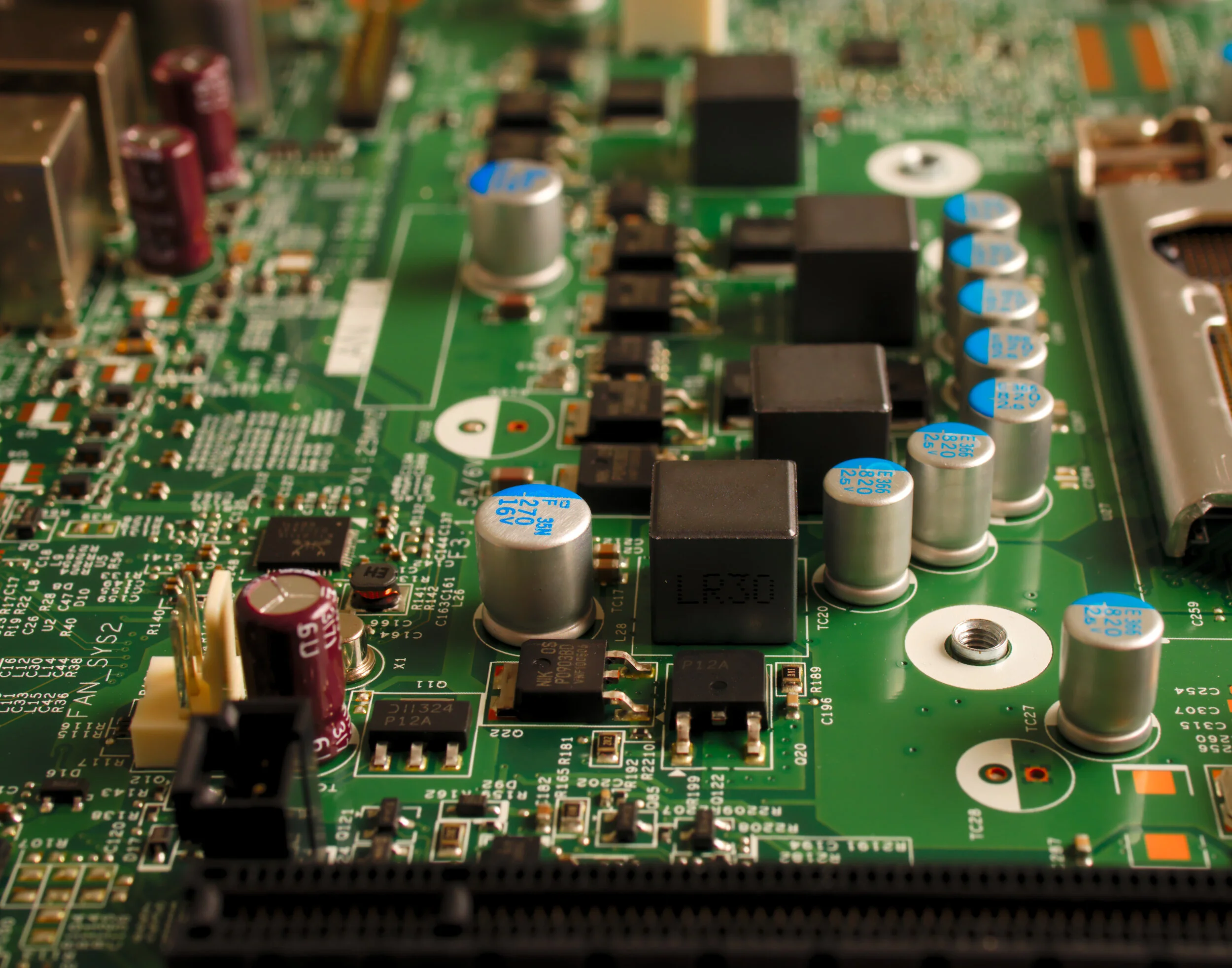

Our products can be found in the manufacturing process for Printed Circuit Board applications for most industrial and consumer electronics including smart phones, computers and sensitive defense applications.

Filtration companies are always looking for alternative solutions to meet their demanding applications and ever-changing media needs. Fortunately, Omnia has been there to meet these challenges with proven success from Automotive Filtration to Food and Beverage solutions.

Omnia manufactures highly absorbent media for World-Class technology leaders who provide patented technology for use in hospitals, retail facilities, office buildings, industrial sites, and many other applications where corrosion protection, condensation control, and mold and mildew control are required.

Our products can be found in the manufacturing process for Printed Circuit Board applications for most industrial and consumer electronics including smart phones, computers and sensitive defense applications.

Direct contact with medical instruments and/or hygiene products demand purity and conformity to Federal regulatory standards and statues. Strict control of raw materials and process parameters guarantees consistent product performance and compliance with the highest standards of excellences demanded by various end product applications.

Omnia custom products have proven to withstand temperatures of up to 1,000 °F. Utilizing proprietary materials, formulations and processes, Omnia’s fire- retardant products are manufactured to meet or exceed the rigorous standards set forth by Underwriters Laboratory.

Made from latex reinforce fibers, durability is a key requirement for secondary coating, laminating and embossing. Omnia manufactures base in a variety of custom specified colors and thickness that ultimately become components within wedding/photo albums as well as upscale packaging.

Technical and specialty tapes are designed to meet specific performance criteria and are engineered for specific market sectors such as Automotive, Marine, Aerospace, etc. Omnia manufactures single-side coated tape base with release coatings.

Mulch is often used to improve the microclimate plants grow in causing better growth conditions. Omnia developed an eco-friendly biodegradable paper mulch alternative to traditional plastic mulch, which can contaminate soil conditions and requires disposal at the end of the season.

As well as being eco-friendly, Omnia’s paper mulch can improve plant growth, moisture retention, and weed control creating the potential for higher yield/plant.